Motor Cores which act as the Catalyst to Skyrocket Your Motors Efficiency, Guaranteeing Longevity and Reliability

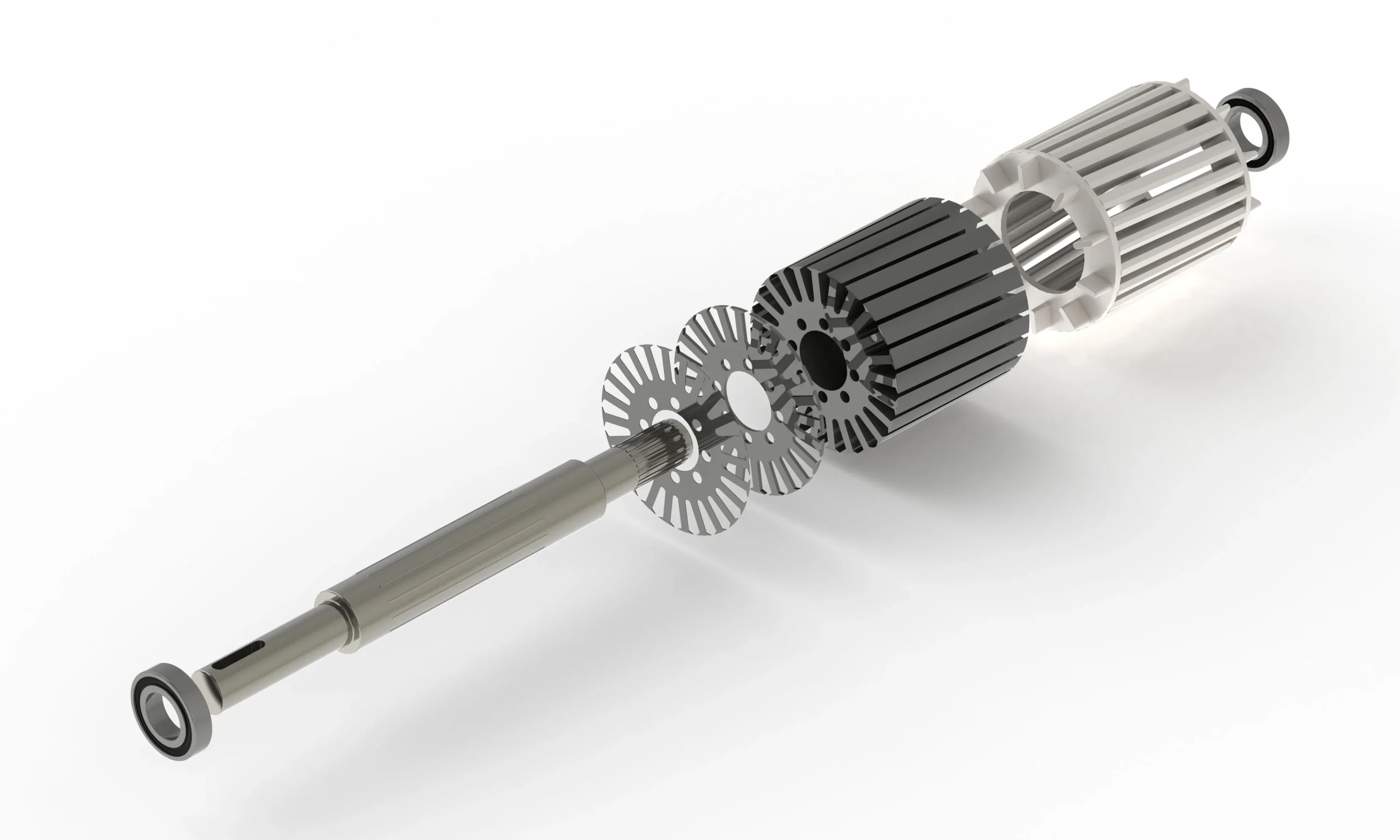

We procure electrical steel from leading mills in India and import from Russia, China, and Europe to address industry scarcity. Our Motor OEMs targeting high efficiency rely on steel grades ranging from CRCA to high-efficiency CRNO steel with watt losses between 2.5 to 12 at 1.5 Tesla. Our cutting-edge tools ensure precision within 2-5 microns per lamination. With steel thickness ranging from 0.3 mm to 1 mm and coatings like C3, C5, and C6, we guarantee problem-free motor operation with standardized quality at every level.

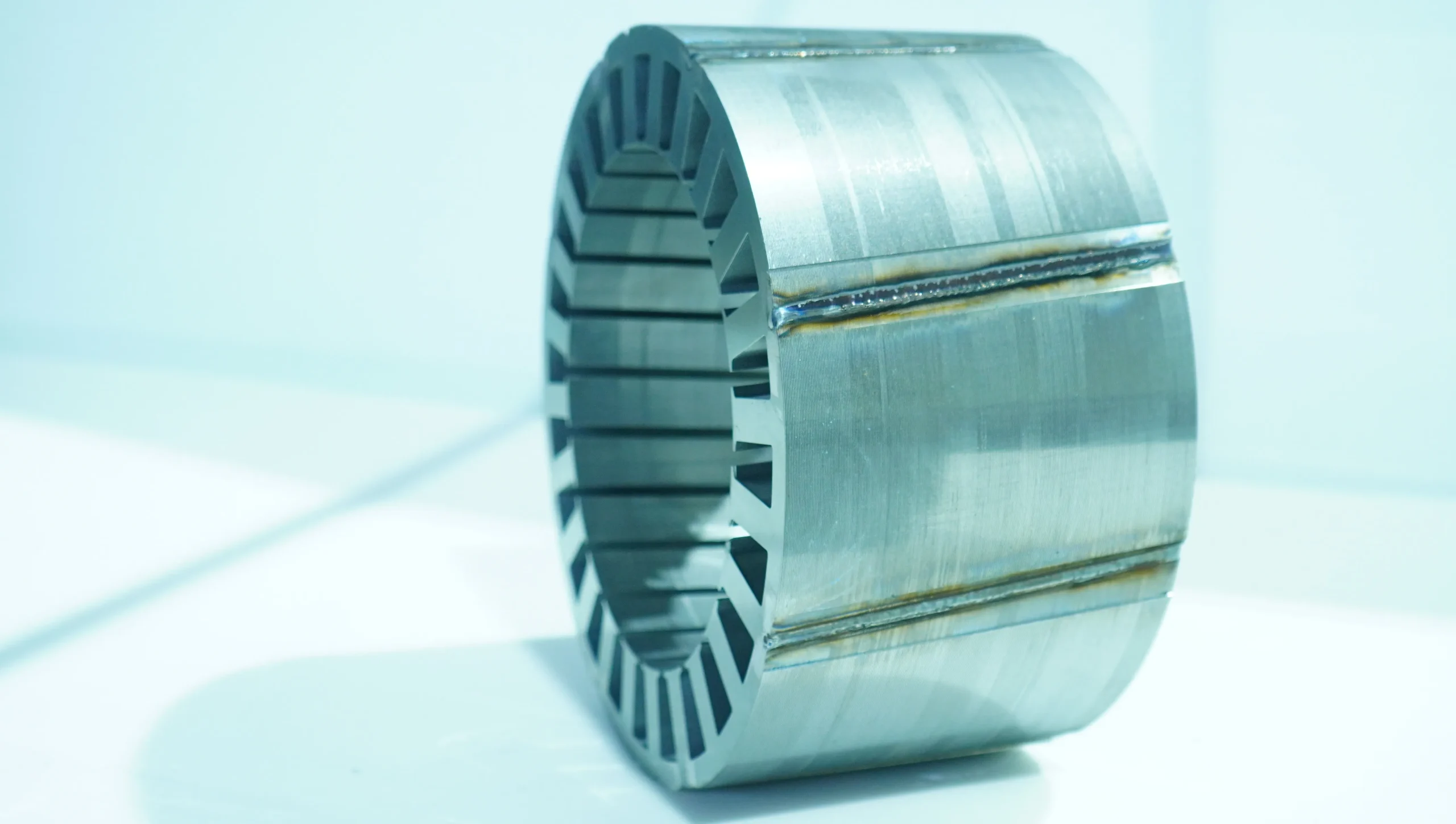

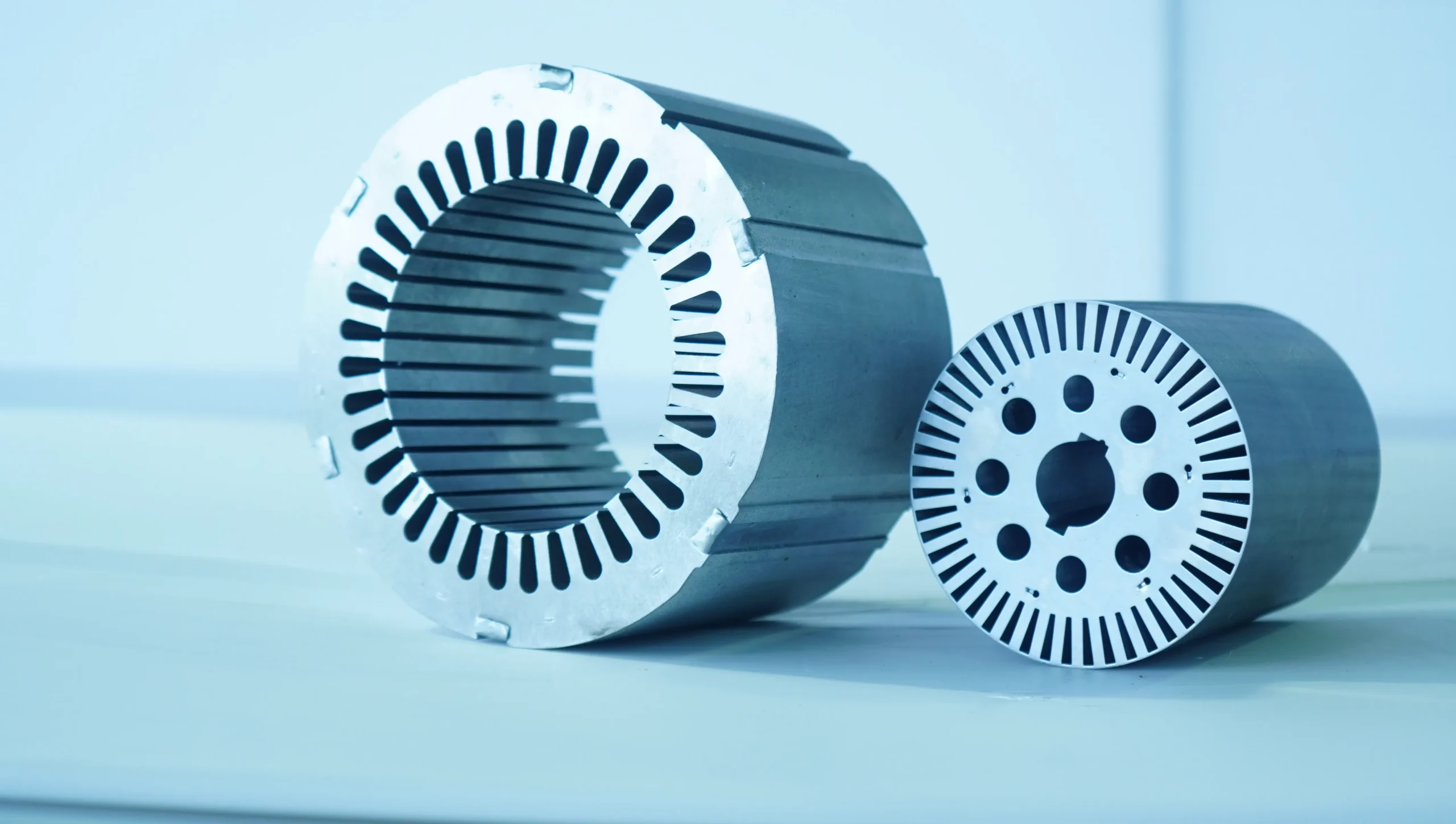

Rotor and Stator Assemblies

Compound Punched Laminations

Notched Laminations

View All Products & Applications